Kūleʻa kila kila e hoʻopau ana i ka hale hana kūʻai pololei

Na Waiwai Kino

1. Aia nā ion chloride i loko o ke kaiapuni hana.

Loaʻa nā ions chloride i ka paʻakai, ka hou, ka wai kai, ka makani, ka lepo, a me nā mea ʻē aʻe. ʻOi aku ka wikiwiki o ke kila kila ma ke alo o nā ion chloride ma mua o ke kila māmā maʻamau.

No laila, loaʻa i ka hoʻohana ʻana i ka ʻenehana stainless steel nā koi, a me ka pono e holoi pinepine, wehe i ka lepo, mālama maʻemaʻe a maloʻo.(Hāʻawi kēia iā ia i kahi "hoʻohana kūpono ʻole.")

Aia kekahi laʻana ma ʻAmelika Hui Pū ʻIa: ua hoʻohana kekahi ʻoihana i kahi pahu ʻoka e hoʻopaʻa i kahi hopena i loaʻa nā ion chloride.Ua hoʻohana ʻia ka pahu no hoʻokahi haneli mau makahiki a ua hoʻolālā ʻia e pani ʻia i nā makahiki 1990.No ka mea, ʻaʻole lawa ka mea ʻoka i kēia manawa, ua ʻino ʻia ka ipu a ua hū i nā lā 16 ma hope o ke pani ʻia ʻana me ke kila kila.

2. ʻAʻohe lāʻau lapaʻau.

ʻAʻole i hoʻoheheʻe ʻia nā mea huila i loko o ka matrix, ka hopena i ka haʻahaʻa haʻahaʻa i loko o ka hoʻolālā matrix a me ke kūpaʻa maikaʻi ʻole.

3. ʻO ia mau mea me ka ʻole o ka titanium a me ka niobium he ʻano kūlohelohe i ka intergranular corrosion.

ʻO ka hoʻohui o ka titanium a me ka niobium, i hui pū ʻia me ka mālama paʻa, hiki ke hōʻemi i ka corrosion intergranular.

I loko o ka lewa a i ʻole kemika corrosion medium hiki ke pale aku i ka corrosion o ke kila kila kiʻekiʻe, ʻo ke kila kila he ili nani a maikaʻi ke kūpaʻa ʻana i ka corrosion, ʻaʻole pono e uhi ʻia a me nā lāʻau lapaʻau ʻē aʻe. nui nā ʻano o ke ʻano kila, ka mea maʻamau i kapa ʻia he kila kila.Ma ka inoa o ka hana o 13 chromium kila, 18-8 chromium nickel kila a me nā kila kila kiʻekiʻe.

Mai ka metallographic manaʻo, no ka mea, kuhiliʻole kila i chromium a me ka ili o ka hookumu ana o ka loa lahilahi chromium kiʻiʻoniʻoni, ka kiʻiʻoniʻoni kaawale mai ka oxygen i loko o ke kila invasion o corrosion kū'ē.

No ka mālama ʻana i ke kūpaʻa corrosion i loko o ke kila kila, pono ke loaʻa i ke kila ma mua o 12% chromium.

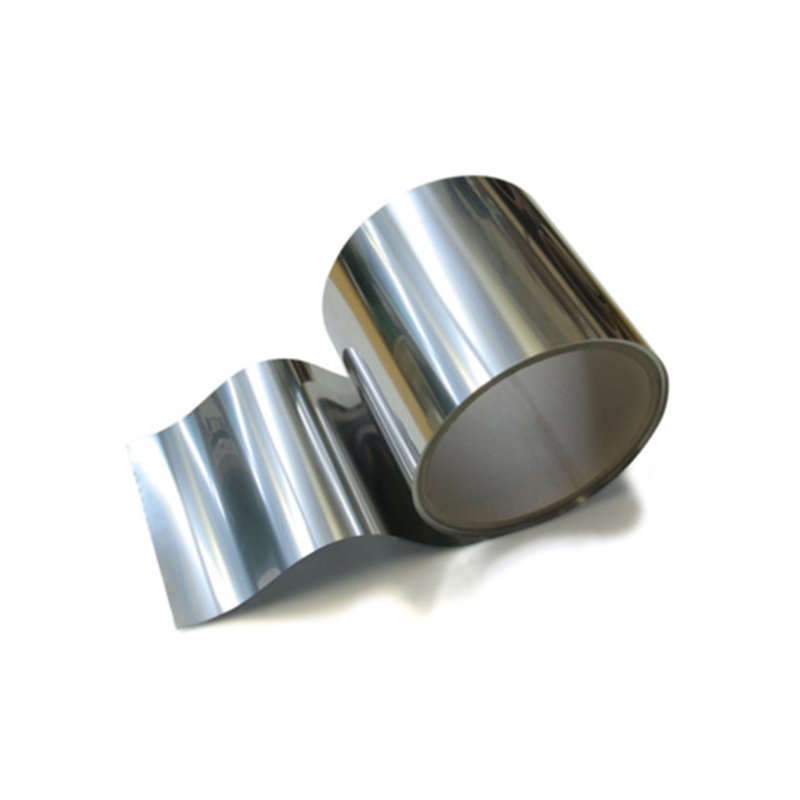

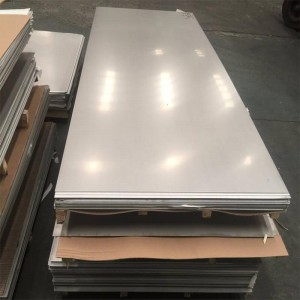

ʻO 304stainless steel Shim Plates he kila kuhiliʻole honua, i hoʻohana nui ʻia i ka hana ʻana i nā mea hana a me nā ʻāpana e koi ana i nā waiwai piha maikaʻi (ke kūpaʻa corrosion a me ka formability).

ʻO ka 304 stainless steel kahi hōʻailona o ke kila kila i hana ʻia e like me nā kūlana ASTM ma ʻAmelika Hui Pū ʻIa.Ua like ka 304 me ke kila kila 0Cr19Ni9 (0Cr18Ni9) o Kina.Aia ka 304 i ka 19% chromium a me 9% nickel.

ʻO 304 ka mea hoʻohana nui ʻia ke kila kuhiliʻole/wela.Hoʻohana ʻia i nā mea hana meaʻai / xiton chemical lako / nuklea ikehu, etc.

ʻO 304 e pili ana i ka inoa Kina 0Cr18Ni9,1Cr18Ni9Ti, ʻona kalapona ≤0:08%

ʻO 304LShim Plates he ʻano like ʻole o 304stainless steel Shim Plates stainless steel me ka haʻahaʻa carbon content a hoʻohana ʻia no nā noi wili.ʻO ka maʻiʻo kalapona haʻahaʻa e hoʻemi i ka ua carbide i loko o ka wahi wela kokoke i ka weld, hiki ke alakaʻi i ka corrosion intergranular (welding erosion) i ke kila kila ma kekahi mau kaiapuni.

Nā ʻāpana

| T | paakiki | paakiki | ʻO ke kūlana hoʻomaʻamaʻa wela paʻakikī ka ua | conductive% | ||||||

| paakiki | paakiki | Ka ikaika huaN/mm | Ka ikaika uʻiN/mm | elongation% | Hoʻomaʻamaʻa wela | paakikiHV | Ka ikaika huaN/mm | Ka ikaika uʻiN/mm | ||

| 301-CSP | 1/2H | 340±30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4H | 400±30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460±30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510±20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304-CSP | 1/2H | 280±30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4H | 340±30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631-CSP | 0 | ≤200 | - | ≤1030 | ≥20 | TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2H | 375±25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4H | 425±25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||